Global Controlled-Release Flavor Systems Market Outlook 2026–2036: Growth, Segmentation, and Demand Trends

Industry growth reflects rising demand for sustained flavor perception, processing-stable delivery systems, sequential taste experiences across packaged foods.

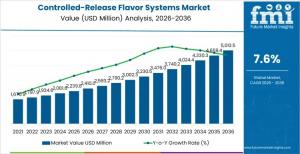

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The controlled-release flavor systems market is poised for significant growth over the next decade, with a forecasted compound annual growth rate (CAGR) of 7.6% from 2026 to 2036. Market valuation is expected to more than double, reaching approximately USD 5,013.5 million by 2036. This growth reflects increasing industry reliance on advanced flavor delivery architectures that modulate timing, intensity, and persistence of flavors, moving beyond simple aroma enhancement.

Controlled-release flavor systems are critical in a range of consumer products—such as chewing gum, confectionery, instant beverages, and fortified foods—where preserving sensory impact after exposure to heat, moisture, or mechanical stress is essential. These systems address formulation challenges caused by processing methods like baking, extrusion, spray drying, and pasteurization that degrade conventional flavor compounds.

Request For Sample Report | Customize Report |purchase Full Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-31480

Market Context and Industry Relevance

The shift toward controlled-release flavor technologies aligns with evolving consumer expectations for multi-layered taste experiences and longer-lasting flavor perceptions. Products that emphasize extended flavor perception or sequential taste delivery are increasingly viewed as higher quality, especially as sugar reduction and protein fortification alter flavor profiles, often increasing bitterness or off-notes.

Manufacturers select controlled-release systems based on their interaction with variables such as pH, saliva, hydration, or mastication. These systems are designed and tested under real consumption conditions to ensure performance that supports sensory consistency across shelf life and varying climates.

Key Market Insights

• Market Size and Growth: Valued at USD 2,410.0 million in 2026, the market is forecasted to reach USD 5,013.5 million by 2036, growing at a CAGR of 7.6%.

• Leading Release Mechanism: Time-controlled release systems hold the largest share at 34%, preferred for delivering sustained flavor experiences.

• Fastest-Growing Regions: India, China, Brazil, the USA, and the UK lead growth, with India exhibiting the highest CAGR of 8.8%.

• Primary Applications: Chewing gum and confectionery dominate demand at 38%, followed by beverages and instant drink mixes at 22%.

Segmentation by Release Mechanism, Delivery Matrix, and Application

Release Mechanisms:

• Time-controlled release (34%) provides gradual flavor delivery over extended consumption periods.

• pH-triggered release (27%) activates flavor in response to oral or gastrointestinal conditions.

• Moisture-activated release (21%) releases flavor upon exposure to saliva or hydration.

• Mechanical action release (18%) depends on chewing or mastication forces.

Delivery Matrices:

• Carbohydrate-based matrices (36%) are favored for their film-forming properties and predictable dissolution.

• Polymer and protein matrices (28%) offer structural tuning and environmental responsiveness.

• Lipid-based systems (22%) protect flavors from moisture and enable delayed release.

• Hybrid multilayer systems (14%) combine materials for staged flavor release.

Applications:

• Chewing gum and confectionery (38%) require prolonged and sequential flavor delivery.

• Beverages and instant drink mixes (22%) benefit from controlled flavor bursts and minimized flavor loss.

• Bakery and snack foods (17%) utilize flavor protection against processing stresses.

• Nutritional and functional foods (13%) balance sensory acceptance with bioactive ingredient masking.

• Oral care and specialty foods (10%) use timed flavor perception for extended sensory impact.

Regional Market Dynamics

India: Growth is driven by packaged food and nutraceutical sectors addressing complex flavor stability amid high ambient temperatures and lengthy distribution. Adoption favors cost-efficient multi-function systems compatible with processes like spray drying and extrusion.

China: Industrial food processors emphasize consistent sensory outcomes across large-scale production, supporting demand in ready-to-drink beverages and fortified nutrition products. Domestic suppliers are scaling encapsulation technologies to meet these needs.

Brazil: Manufacturers focus on flavor stability in tropical climates, with demand concentrated in mass-market beverages and confectionery where aroma retention and sweetness perception are critical.

USA: Demand is shaped by reformulation of functional and fortified foods requiring bitterness management and clean label considerations, emphasizing uniform flavor experience nationwide.

UK: Nutrition policies and retailer standards are pushing reformulations towards sugar reduction and protein enrichment, increasing reliance on delayed flavor release systems.

Industry Challenges and Technical Considerations

The design and development of controlled-release flavor systems involve navigating technical complexities related to ingredient stability, regulatory classifications, and manufacturing scalability. Systems must maintain efficacy under varying pH levels, heat exposure, and mechanical stresses, extending development timelines and investment needs.

Regulatory variations influence material selection and labeling, impacting market entry strategies and cross-border applicability. Cost constraints favor targeted use in products where sensory differentiation justifies advanced formulation efforts.

Competitive Landscape

Leading global players shaping the controlled-release flavor systems market include:

• Givaudan: Known for proprietary encapsulation and sensory modeling technologies.

• International Flavors & Fragrances (IFF): Integrates controlled-release within broader taste modulation platforms.

• Symrise: Focuses on confectionery and functional nutrition controlled-release solutions.

• DSM-Firmenich: Aligns flavor delivery with processing stability and sensory consistency goals.

• Sensient Technologies: Emphasizes scalable encapsulated systems with reproducible flavor release.

Market competition centers on release precision, customization capability, sensory performance reliability, and collaborative development with product formulators.

Outlook

As the food, beverage, and nutraceutical industries face rising demand for complex, multi-layered sensory experiences, controlled-release flavor systems are set to become increasingly indispensable. Their ability to protect delicate flavor compounds during processing and orchestrate precise flavor release during consumption supports innovation in reduced sugar, protein-enriched, and functional products worldwide.

The market’s evolution reflects not just volume growth but a refined focus on functional precision and resilience under diverse processing and consumption conditions, establishing controlled-release flavor systems as a cornerstone technology in future food formulation strategies.

Browse Related Insights

Liquid Flavors Market: https://www.futuremarketinsights.com/reports/liquid-flavors-market

Australia Sweetener Market: https://www.futuremarketinsights.com/reports/australia-sweetener-market

Europe Sweetener Market: https://www.futuremarketinsights.com/reports/europe-sweetener-market

Latin America Sweetener Market: https://www.futuremarketinsights.com/reports/latin-america-sweetener-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.